Capabilities

Compounding

Our compounding division is equipped to provide exactly the rubber material you need.

While most customers choose to have us mold their parts, others mold their own in-house. Either way, we can provide quality rubber material to your specifications.

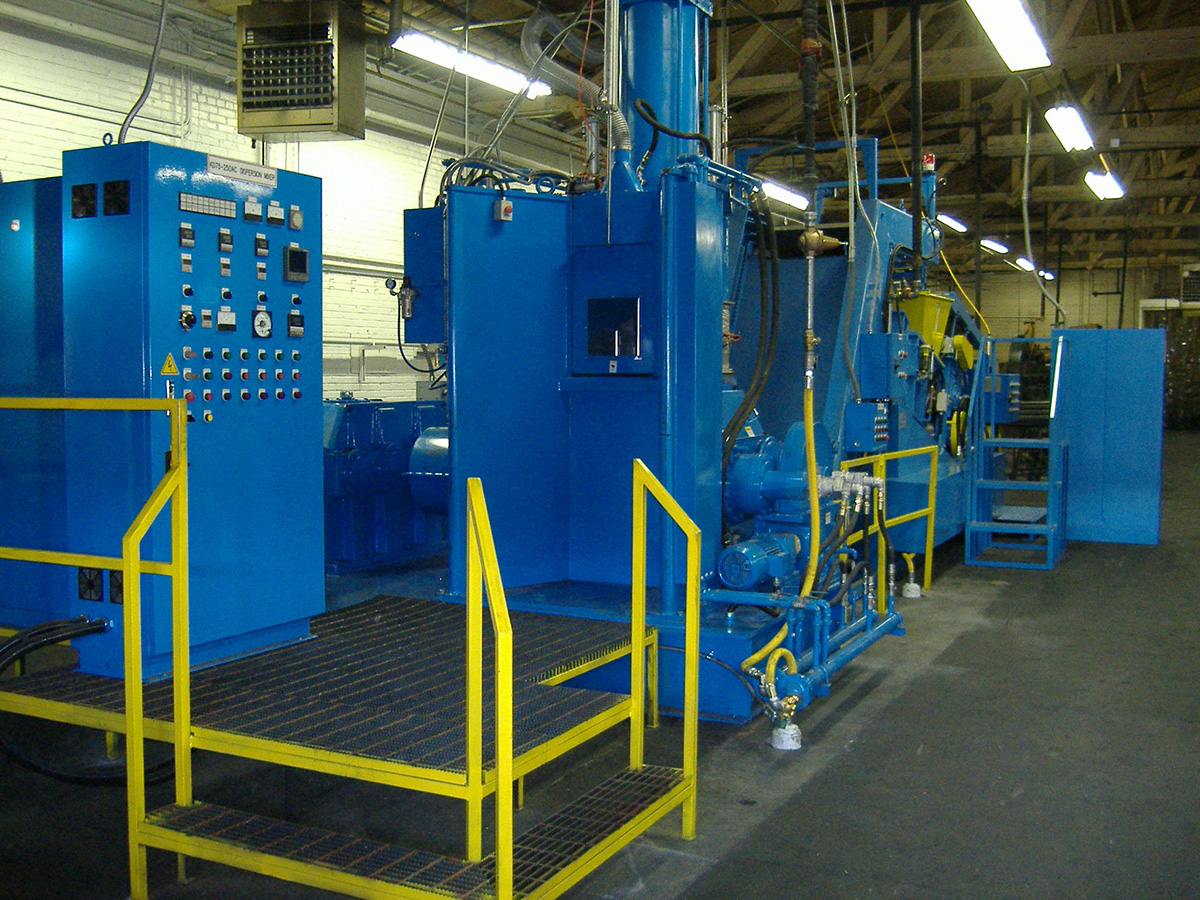

Mixers & Mills

Mixers & Mills

We’re equipped with a variety of mixers and mills. The size of each machine determines the amount of material that can be mixed at once.

Our machines include:

- 2 Tilt Body Dispersion mixers, 55 – 75 liter

- 3 Open Roll Mixing Mills, 50” up to 60”

Rubber Material

Our years of creating and modifying formulas in-house have resulted in a library of hundreds of formulas to meet many different needs. If one of our formulas doesn’t fit your requirements, we can find one that does. We can also use your own specified formula.

Some of the common characteristics and specifications we’re asked to meet every day include:

- Non-marking

- Non-conductive

- Food grade

- Medical grade

- Color matching

- Oil-resistant

- UV-resistant

- Gas- & Chemical-resistant

- ASTM D2000

- SAE J2000

Types of Rubber

There are many types of rubber, each with its own strengths and weaknesses. We’ve worked with enough rubber material to know the pros and cons of each, and we can help you determine the best material for your application. The more common rubber types we work with are listed below:

- Natural Rubber (NR): Good tear and abrasion properties and tensile strength

- SBR (Buna-S): Good impact strength while flexible at low temperatures

- Neoprene (CR): Moderate oil-resistance, good flame-resistance, and some ozone-resistance

- EPDM: Good resistance to heat, ozone, and sunlight, and retains flexibility at low temperatures

- Nitrile (Buna-N): Superior resistance to petroleum-based hydraulic fluids, and very good resistance to gasoline and oil

- Butyl (IIR): Superior impermeability to gasses and strong weatherability

- Silicone (SI): Good resistance to weather, ozone, and sunlight, and performs well in high heat and cold conditions

- Fluorocarbon Viton (FKM): Tolerates high-temperature applications, and is resistant to fuel, oils, and hydrocarbon fluids

- Epichlorohydrin (ECO): Great heat, oil, and petrol resistance

- Hypalon (CSM): Able to withstand temperature extremes and ultraviolet light, and is chemical-resistant

- Polyurethane (PU): Good for making flexible, high-performance, high-strength molds

- Polysulfide: Has a pronounced tendency to relax and flow under pressure, and is not affected by sulfur or moisture

- Polynorbornene (PNR): Shows excellent mechanical strength, water-resistance, and adhesion to metals

We offer compounding material in various forms.

Our compounding division delivers rubber material in a myriad of different ways, depending on how the compound will be worked to create the end product. The three most common forms are:

- Extruded: up to 6” diameter or custom pre-formed shape

- Slab: 1/8” – 1” thick, typically dependent upon the material type

- Strip: 1/2” x 3/8” up to 3” x 3/4”

Global Supply Sourcing

We offer cost sensitive rubber parts from overseas suppliers as well as many different other types of off-shore products. Our Global Supply Sourcing program can turn your headaches into positive cash flow.

Benefits of global supply sourcing include:

- Reduces your overhead and input costs

- Saves you time

- Lowers your risk